Comparing Pallet Runner™ to Traditional Dynamic Storage

Comparing Pallet Runner™ to Traditional Dynamic Storage

Pallet Runner™ vs. Traditional Storage

For optimal management of high-volume pallet storage and retrieval operations, dynamic rack systems such as pushback, drive-in, or pallet flow present viable solutions for achieving high-density storage within a warehouse environment. However, it’s important to note that each of these systems comes with its own set of limitations that need to be carefully considered. In specific scenarios, the implementation of a Pallet Runner™ system might emerge as a more fitting choice to accommodate the diverse requirements of various operations.

It’s essential to acknowledge that the costs and limitations associated with each storage method are distinct and should be evaluated comprehensively before making a decision. Here is a breakdown of these factors for your consideration:

| Drive-in | Pushback | Pallet Flow | Pallet Runner™ | |

|---|---|---|---|---|

| Product Flow | L.I.F.O. | L.I.F.O. | F.I.F.O. | FIFO / L.I.F.O. |

| Max Storage Depth** | 12 | 6 | 15 | Unlimited |

| SKU Selectivity | Per Bay | Per Lane | Per Lane | Per Lane |

| Load/unload lift truck position | Drives in | Drive Aisle | Drive Aisle | Drive Aisle |

| Range of Investment | $ | $$ | $$$ | $$ |

Product storage and flow – LIFO or FIFO

LIFO Applications

LIFO (Last-In, First-Out) stands as a conventional method for pallet storage, commonly employed within traditional dynamic storage systems. However, it’s worth noting, that while most dynamic systems adhere to the LIFO principle, pallet flow systems, function as FIFO (First-In, First-Out) with Pallet Runner™ systems offering both storage flows. While dynamic storage offers a substantial advantage in space efficiency, a potential limitation lies in the restricted accessibility to stored pallets. With a good understanding of what you’re storing, how that product enters and exits the storage system and the guidance of a professional these limitations can be reduced if not eliminated.

In contrast, a selective pallet rack system may not accommodate as many pallets, yet it guarantees unhindered access to all pallets at any given time. This attribute proves particularly valuable for scenarios where accessibility is paramount and/or you’re storing a small number of pallets per SKU

Pushback and drive-in systems operate on the LIFO principle, making them particularly suitable for applications necessitating deep lane storage. These systems prove advantageous for scenarios involving higher picking volumes but a more limited range of SKUs.

The adaptability of Pallet Runner™ is noteworthy, as it can be configured to function as either FIFO or LIFO systems. In LIFO operations, where loading and unloading transpire within a single lane, pallet shuttles tend to be more frequently employed.

In summary, the choice between LIFO and FIFO storage methods, as well as the selection of dynamic or selective rack systems, hinges on a careful consideration of operational requirements and access priorities. Each approach carries its own set of advantages and limitations that must be evaluated to determine the best fit for specific warehousing needs. When an in-depth elevation of what needs to be stored is carried out it is very common for the overall design to include multiple storage mediums.

FIFO Applications

Pallet Runner™ and pallet flow storage systems operate on the principle of FIFO (Pallet Runner™ can work LIFO as well), ensuring that the first pallet to be stored is the first to be retrieved. Notably, both systems are designed to simplify the operator/lift truck role to the mere task of accessing the pallet presented by the system. When employing Pallet Runner™, additional productivity and utilization gains can be achieved by utilizing them for comprehensive loading or unloading of entire levels, optimizing their efficiency in both pallet flow and Pallet Runner™ systems, the operational setup necessitates the presence of two aisles: one designated for loading and the other for access. This dual-aisle arrangement ensures a streamlined flow of pallets while maintaining the FIFO sequence.

It’s important to recognize that FIFO systems, with their dynamic components such as shuttles or flow rails, demand periodic maintenance. However, a key advantage lies in the enhanced safety, as forklifts are never required to enter the intricate storage structure. This design choice minimizes potential safety risks associated with forklift movements within the storage system.

Pallet Depths

The primary objective underlying all these systems is to achieve higher pallet storage density within a confined area. Nevertheless, it’s worth noting that a trade-off exists between increased pallet storage and accessibility, particularly pronounced in the case of drive-in systems. Our comparative analysis reveals that pallet flow and Pallet Runner™ systems outperform drive-in and pushback systems regarding pallet storage capacity within a single lane, thus showcasing their superior space utilization efficiency.

Expanding on this notion, Pallet Runner™ systems emerge as the pinnacle regarding of pallet storage potential among these methods. Their advantage stems from their independence from gravity or the need for forklifts to navigate within the system. This unique attribute contributes significantly to their capacity to store more pallets in comparison to alternative systems.

In essence, the pursuit of optimal pallet storage efficiency revolves around striking a balance between maximizing storage volume and ensuring feasible access. Pallet flow and Pallet Runner™ systems have proven to be front-runners in this endeavor, characterized by their ability to house an impressive number of pallets while circumventing some of the limitations posed by traditional gravity-dependent or forklift-reliant setups.

SKU Selectivity

As storage density increases, selectivity tends to decrease. Traditional selective racks offer the flexibility to access any pallet at any time, which makes them ideal for managing low-volume, high-SKU inventory. On the other hand, dynamic storage systems are tailored for high-volume operations with a low number of SKUs.

When it comes to drive-in systems, they are typically constrained to storing a single SKU per bay. The drawback of drive-in systems is that they require loading and unloading to happen sequentially from top to bottom, resulting in a relatively low space utilization rate of approximately 50%.

In dynamic systems, each level of the bay is available independently of the other levels. Pushback, flow, and shuttle systems offer the advantage of storing different SKUs in each lane, enhancing selectivity. Utilization available via these options depends on multiple factors, but based on the correct analysis of SKU, utilization rates can exceed 90%. Consequently, using of a dynamic storage system can effectively double the number of pallets stored compared to traditional drive-in systems.

Cost always plays a big factor in the analysis of storage systems, and ultimately, it’s an investment that needs to be reviewed carefully. Based on what has been described above, you need to look at the costs in more depth than just the initial apparent cost presented to you.

Example:

The company initially determined their storage needs to be 1,000 pallets, and they were presented with proposals for both drive-in and Pallet Runner™ storage systems. At first glance, the drive-in system seemed significantly more cost-effective than the Pallet Runner™ system. However, upon conducting a more thorough analysis of both options, they discovered several substantial differences:

Pallet Positions: Considering the requirement to store 1,000 pallets and the utilization of the drive-in system, it became apparent that the company would need to acquire nearly 2,000 pallet positions.

Square Footage: With the increased number of pallet locations necessary for the drive-in system, the square footage requirement doubled, impacting both space utilization and costs.

Operational Efficiency: The distinct operational characteristics of the two systems indicated that the drive-in system would necessitate an increased number of operators to manage effectively.

Damage Reduction: The potential reduction or elimination of both product and system damage had to be factored in, as it could lead to cost savings and improved overall efficiency.

When considering all these factors, the initial cost difference between the two systems appeared much smaller than it originally appeared. Therefore, a comprehensive evaluation was crucial to make an informed decision about the most suitable storage solution.

Forklift Interactions

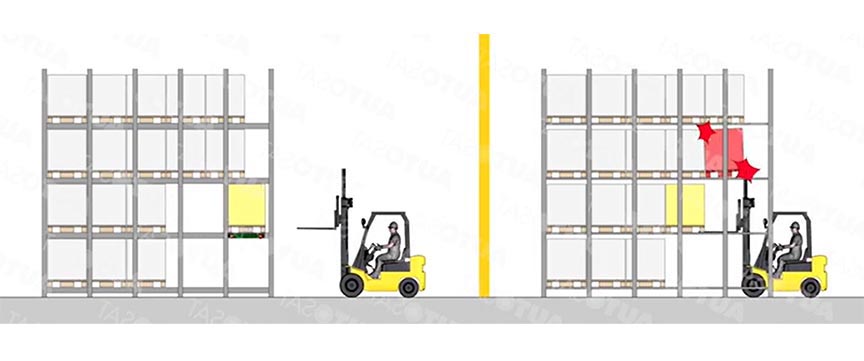

In traditional warehouse pallet racking systems like selective, very narrow aisle (VNA), or double-deep, forklifts typically position the pallet from the aisle to the front of the rack.

However, when implementing a drive-in system, there’s a fundamental difference: the forklift operator is required to enter the rack structure to store and retrieve pallets. This stands in contrast to pallet shuttle, pushback, and pallet flow systems, where pallets are conveniently placed at the front of the rack.

The act of entering a drive-in system inevitably leads to potential damage to the racking structure, the operator’s safety, and the integrity of the pallet load. Picture navigating a forklift into or out of a drive-in system with a pallet suspended 40 feet in the air – it’s a scenario fraught with risk.

Summary

Dynamic storage systems, while pricier than selective storage, prove indispensable when dealing with a substantial quantity of pallets in your warehouse. These systems find particular utility in refrigerated spaces, where space is at a premium and must be maximally utilized. They offer essential efficiency in storage solutions.

Here’s an overview of various dynamic storage systems, each with its unique characteristics and cost considerations:

Drive-in Systems (LIFO): Among the most economical options, drive-in systems don’t rely on additional components. However, they do suffer from inevitable damage and necessitate regular maintenance and repairs, potentially offsetting initial cost savings.

Pushback Systems (LIFO): Slightly pricier than drive-in systems, pushback systems incorporate nested carts and engineered components like bearings. This added complexity can contribute to increased upfront costs.

Pallet Flow Systems (FIFO): Pallet flow systems are the costliest within the high-density dynamic systems category. Their expense arises from the inclusion of roller and braking systems that extend the entire length of the lane, enhancing both functionality and cost.

Pallet Runner™Systems (FIFO/LIFO): Pallet shuttle systems tend to align with the cost per pallet of pushback systems. However, additional expenses are incurred due to the inclusion of shuttles, power requirements, and maintenance, which should be factored into the overall cost assessment.

In conclusion, while dynamic storage systems may present a higher initial investment than selective racks, they offer indispensable benefits, especially when dealing with large pallet quantities. It’s essential to consider the specific needs of your warehouse and the long-term operational advantages these systems can provide when assessing their overall value.

For more information on how Automha Americas can make your warehouse facility operationally more efficient, contact us by email, info@automhaamericas.com, or fill out the form below.

Steve Dale, Vice President

Automha Americas Automation Corp.